- Carpet yarn processing equipment

- Wire making equipment

- Best seller

- Peripheral parts

- Certification and Honor

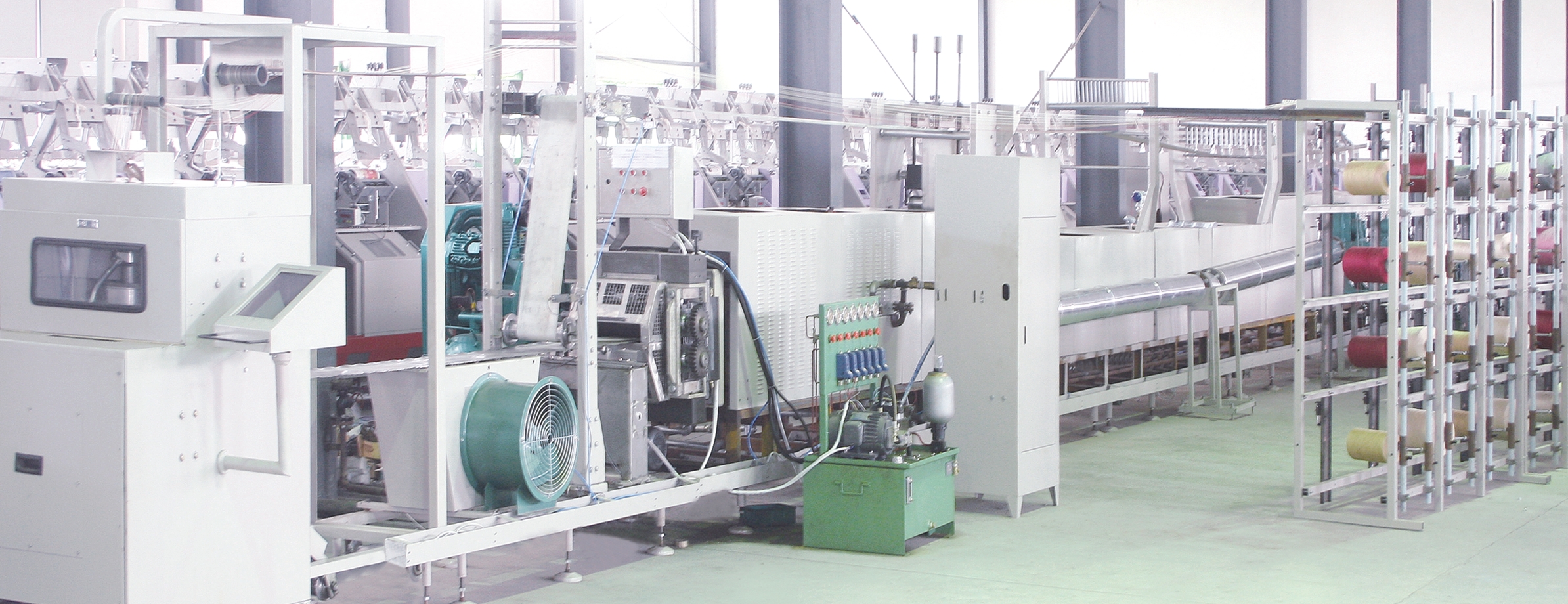

- Factory and Equipment

Features:

Multi-point detection, PC microcomputer digital control, low labor intensity

Optimization design of each part, Compact structure, less floor space.

Humanized design, succinct man-machine interface talk function, easy operation

Energy-conservation design, energy consumption is only 1/10 of other machines of the same performace, greatly saving energy and reducing the production cost

Easy maintenance, lower maintenance cost

Function:

Improve the affinity among the molecule of yarn and dyestuffs, guarantee the stability of the color of yarn

Dispel the stress within the yarn, strengthen wear-resisting degree and elasticity of yarn

The fine hair is strong that forming a cluster, improve the coverage rate of the yarn in the carpet.

Applied yarns:

Wool, PA, PP, Acrylic, PET, Nylon6, Nylon66, BCT, etc.

Technical Specificaitons:

Number of Yarn: 18, 24, 36

Max. Feeding speed: 400m/min

Applicable yarn: 500-3000D

Winding way: automatic

Max. winding speed: 800m/min

Winding bobbin size: ◎80*◎75*290

Yarn roll size: ◎300*254

Setting oven: 3m/section, steam heating

PREV:test productsd